Diamond Abrasive Sticks for Cast Iron Ceramics and Glass Honing

Metal Bonded Diamond Honing Sticks, Superabrasive Diamond Stones BOSON diamond and CBN honing stones are suitable for mo;

Basic Info

| Model NO. | 60*3*2 |

| Specification | 60*3*2 |

| Trademark | BOSON ABRASIVES |

| Origin | China |

| HS Code | 6804219000 |

| Production Capacity | 20000 PCS/Month |

Product Description

Metal Bonded Diamond Honing Sticks, Superabrasive Diamond StonesBOSON diamond and CBN honing stones are suitable for mounting on honing tools of all brands and designs. The extreme hardness of the cutting grain and bond result in excellent cutting efficiency in connection with a long service life.

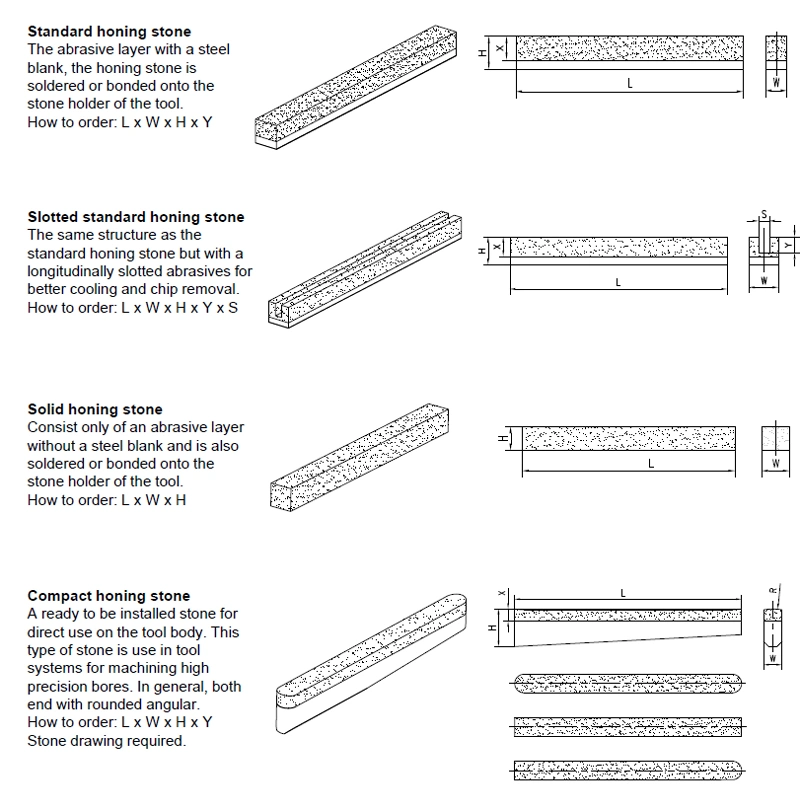

Our diamond and CBN honing stones (abrasive sticks) are available as standard diamond stick to fit to the steel carrier. Alternatively, we can supply the honing stick ready for fitting as a diamond stick with expansion profile. This minimizes the preparation required in your company. For special requirements we also supply the honing sticks in the following special forms:

Bore Types:The following bore errors can be correct by honing:

BOSON Abrasives supply four types of honing stones for honing different materials:Diamond (D) - Metal bonded excellent for accelerated stock removal and long abrasive life in cast iron, carbide, titanium, silicon carbide and other exotic materials.Cubic Boron Nitride (CBN) - Metal bonded excellent for accelerated stock removal and long abrasive life in ferrous material.

How to order

When order, please provide the honing machine name and no. of spindle. Workpiece drawing, Component material and hardness, stock removal amount for each process, surface quality requirement ( Ra, Rvk, Rpk, Rv, Roundness Cylindricity). Our technician will recommend the most suitable specification for your application.

You may also like

Send inquiry

Send now